July 2013

MEMBERSHIP

Renewing Distinguished Member

Renewing Supporting Members

- UNICOR

- Trex

- American Chemistry Council

New Supporting Member

- Green Tree Textiles

Renewing Supporting Member

- Connecticut Recyclers Coalition

NERC NEWS

- Organics Management Selected as Theme for NERC's Fall 2013 Conference

- NERC Moves Forward on Green Purchasing Project: Products Selected

- ISRI R2/RIOS Continues with Sponsorship of the State Electronics Challenge

- NERC's Blog Worth Repeating: Organics Recycling = Composting

TOXICS IN PACKAGING CLEARINGHOUSE NEWS

STATE UPDATES

Vermont

ADVISORY MEMBER NEWS

OF GENERAL INTEREST

|

NERC's mission is to advance an environmentally sustainable economy by promoting source and toxicity reduction, recycling, and the purchasing of environmentally preferable products and services. |

State and Advisory Member Updates, as well articles of General Interest and guest blogs are provided as submissions to NERC and may not reflect the policy or position of the Northeast Recycling Council, Inc.

NERC is an equal opportunity provider and employer.

MEMBERSHIP

We are delighted to thank Samsung for continuing its Distinguished Membership and support of NERC. We also thank the several Sustaining Members that have recently renewed their memberships: UNICOR, Trex, and the American Chemistry Council (ACC). And, a new Supporting Member has joined. We welcome Green Tree Textiles to the NERC family. And also thank the Connecticut Recyclers Coalition (CRC) for renewing its Supporting Membership.

A hallmark of NERC is the strength of multi-stakeholder involvement and problem solving. This is a direct result of the active participation and support of NERC's Advisory Members. NERC has more than 50 Advisory Members. To see a complete listing and the benefits of membership, visit the NERC Advisory Membership web page.

The broad spectrum of interests represented by NERC's Advisory Members and Board Members and their willingness to participate significantly contribute to the unique and important role that NERC plays in recycling in the region.

NERC NEWS

Organics Management Selected as Theme for NERC's Fall 2013 Conference

In the Northeast, there is growing interest and concern over organics management. As illustrated in the waste characterization studies completed by individual states, organics ranks from a low of 20.6% of the solid waste stream in Massachusetts to a high of 43.28% in Maine. State environmental agencies are actively refocusing their efforts to address the diversion of this material from landfills.

NERC's Conference will delve into the issues impacting the organics management industry sector in the Northeast, including:

- State policies and regulations – Explore the Northeast states' perspectives on organics management.

- Options for managing organics – Update on current opportunities, the requirements for program implementation, and available resources.

- Marketing options and the requirements necessary to sustain a profitable operation.

The agenda and registration form will be posted on the NERC website by the first week in August.

The Conference will be held on October 29–30 at the Hotel Northampton in Northampton, Massachusetts. Plan on being there!

Conference sponsorships and exhibit space are available.

For more information, contact Mary Ann Remolador, NERC's Assistant Director & Conference Organizer.

NERC Moves Forward on Green Purchasing Project: Products Selected

NERC received a Roy A. Hunt Foundation grant to write specifications for three products that purchasers find difficult to purchase green. The three products selected for new specs are:

- Printing and writing paper,

- Office products, and

- Toner cartridges.

A group of state purchasers and EPP experts have joined the effort as the project Advisory Committee. They include: Karl Bruskotter, City of Santa Monica, CA; Julia Wolfe, MA Operational Services Division; Ann Wolf, NJ Dept. of Treasury/NJ Dept. of Env Protection; Nancy McIntyre & Cheryl McGurn, RI Division of Purchases; Debbie Damore, VT Buildings & General Services; and Alicia Culver, Responsible Purchasing Network (RPN).

NERC is in the process of developing the teams to write the three specifications. A draft of the specs is scheduled to be ready for review by September. Stay informed about this project via NERC's Email Bulletin and Facebook page. For those experienced in writing EPP specs and that would like to participate in the project, contact Mary Ann Remolador, NERC's Assistant Director and Project Manager.

ISRI R2/RIOS Continues with Sponsorship of the State Electronics Challenge

We are delighted to announce that the ISRI R2/RIOS program has renewed its sponsorship of the State Electronics Challenge. R2/RIOS is committed to demonstrated responsible recycling, as is the Challenge. It is through the commitment and support of organizations that share this vision that the Challenge is able to be a national program that decreases the environmental footprint of office equipment, while saving energy, decreasing the toxicity of products and the waste stream, and promoting responsible recycling.

We are delighted to announce that the ISRI R2/RIOS program has renewed its sponsorship of the State Electronics Challenge. R2/RIOS is committed to demonstrated responsible recycling, as is the Challenge. It is through the commitment and support of organizations that share this vision that the Challenge is able to be a national program that decreases the environmental footprint of office equipment, while saving energy, decreasing the toxicity of products and the waste stream, and promoting responsible recycling.

Please join us in thanking ISRI R2/RIOS for its generosity and support.

NERC's Blog Worth Repeating: Organics Recycling = Composting

NERC's Blog worth Repeating was posted on the NERC Blog on Tuesday, June 2, 2013. It's an article featuring an excerpt from a forthcoming NERC guidance document entitled "Organic Materials Best Management Practices for Rural & Small Towns."

Organics Recycling = Composting

This article continues our ongoing blog series about organics management, with an introduction to home and neighborhood composting options.

Organics recycling — commonly known as composting — is a controlled, aerobic (requiring oxygen) biological process which results in the decomposition of organic materials. This decomposition process occurs naturally in nature. Composting is performed naturally by microorganisms (bacteria, fungi, and other living organisms) which digest the organic residues for food and energy and speed up the decomposition process. The primary end-products are carbon dioxide, water, and compost.

The controlled composting process is created by combining organic materials in proper ratios into containers, piles, or rows; turning or aerating the materials to provide adequate air flow, and, ensuring sufficient moisture to achieve accelerated decomposition. The "finished" material is then allowed to mature through a curing period, resulting in compost.

Compost users include homeowners and municipalities, nursery and greenhouse operators, landscapers, gardeners, farmers, grounds maintenance personnel, golf course managers, transportation departments, land development contractors, and others. The act of composting can be done on a small "decentralized" scale, as in home or backyard composting, or larger scale on farms, or at commercial or municipal operations.

Compost is much different than the raw materials that went into the process. Compost is a stable, humus-like material, free of unpleasant odors, easy to handle, and can be stored for long periods. It is a valuable soil and potting media amendment that, when applied, improves the chemical and physical properties of soil, introducing organic matter, beneficial micro-organisms, and macro-and micro-nutrients, benefiting both the soil and plants.

The benefits of composting and compost use are numerous, including:

- Organics management. An effective way to manage yard waste, brush, food scraps, soiled paper, and other organics to avoid landfill disposal or incineration.

- Value-added product. Composting offers home owners, communities, farms, and private compost businesses with an opportunity to make compost for use or sale.

- Soil quality. Compost is less dense than soil and thus holds more nutrients than soil. It helps to improve soil quality by adding organic matter; moderating soil pH; building cation-exchange capacity (CEC)1 ; enhancing soil porosity; increasing the microbiological ecology of soil; improving water infiltration; and more.

- Water retention. Compost adds organic matter and other qualities which improve the moisture holding capacity of soil.

- Improved soil quality. The application of compost helps to filter pollutants through soil.

- Nutrient recovery. Composting organic materials helps to retain the nutrients present in the organic materials and provides these nutrients in a form for easy plant uptake, reducing the need for synthetic fertilizers.

All composting, whether at home or at a central processing facility, follows a similar process and requires five essential components. These are:

- Feedstock and nutrient balance (Carbon: Nitrogen Ratio). A proper balance of "green" organic "feedstock" materials (e.g., grass clippings, food scraps, manure), which contain large amounts of nitrogen, and "brown" organic "feedstock" materials (e.g., dry leaves, wood chips, branches), which contain large amounts of carbon (but limited nitrogen), is necessary for decomposition.

- Particle size. Smaller feedstock particles allow for more surface area upon which the microorganisms can feed, helping to speed up the decomposition process. Smaller particles help to improve porosity (air flow), produce a more homogeneous compost mixture, and improve pile insulation to help maintain ideal temperatures. Particles that are too small, however, can pack down too much and inhibit air flow. Mowing, grinding, chipping, or shredding materials are effective ways to achieve appropriate particle sizing.

- Moisture content. Moisture is required to keep the microorganisms in compost alive and active. Water helps to transport substances within the compost pile and makes the nutrients in organic material accessible to the microbes. Depending on the type of organic materials being composted, additional moisture may need to be added, either through rainfall or intentional watering.

- Oxygen flow. The microorganisms in compost are "aerobic" — requiring air in order to be active. Aeration helps to speed up the decomposition process. Aeration can be achieved by turning or "mixing" the compost or placing the composting materials on a series of perforated pipes. Adding "bulking agents" such as wood chips and shredded newspaper will also help to aerate the pile. Aeration is essential to keep the decomposition process from becoming anaerobic, which can cause odor problems.

- Temperature. Decomposer microorganisms are active during a certain temperature range. Some microorganisms ("Mesophilic" bacteria) become active at lower temperatures, as these microorganisms work, their activity will cause temperatures to rise. As temperatures go above 120° F other microorganisms ("Thermophilic") will cause the temperatures to rise even higher. These high temperatures are necessary for more rapid composting and to ensure that pathogens and weed seeds are destroyed. Microbial activity can raise the temperature of the pile's core to at least 140° F.

Having the proper nutrient balance, particle size, moisture level, and aeration will ensure that the temperature rises and the compost process is working effectively.

____________________________________

1 Cation-exchange capacity (CEC) is the maximum quantity of total cations, of any type, that a soil is capable of holding, at a given pH value, available for exchange with the soil solution. CEC is used as a measure of fertility, nutrient retention capacity, and the capacity to protect groundwater from cation contamination.

Backyard and Neighborhood Composting

Keeping materials onsite - at home or in neighborhoods - presents rural, semi-rural, and small towns with a relatively low-cost, but effective, organics management program option for virtually all organic wastes. Such "decentralized" composting programs have many benefits, including relatively low startup costs. These programs require residents to play an active part in the organics management effort and help to create a sense of personal responsibility for organics management.

A well organized and promoted backyard or neighborhood composting program can divert substantial amounts of organic materials without the need for municipal or private collection, transportation, or processing. These benefits are especially magnified when combined with organics reduction efforts such as grasscycling and leaf mulching.

Communities benefit from lower disposal costs and reduced organics management requirements. In the long-term, backyard and neighborhood composting efforts can reduce or eliminate the need for municipal composting sites and helps to reduce the need for more landfill space or incinerator capacity. Residents save on trash or yard waste collection fees in areas where collection fees are applied on volume or weight of materials disposed. Backyard and neighborhood composting creates a compost product that can be used in gardens and on landscaping as a soil amendment, helping to reduce fertilizer input needs.

Decentralized composting applications are not limited to households. Commercial developments, including parks, small-scale horticultural operations golf courses, corporate campuses, and large multifamily residential units, as well as schools, colleges, universities and other institutions with landscaped areas and/or food waste generation can manage their own onsite composting programs.

Trench Composting

The easiest way to compost at home, especially food scraps, is through direct soil incorporation. In trench composting, chopped food scraps are placed in a hole or trench and covered with at least eight inches of soil. For use of this method in the winter, a large trench can be dug in the fall, such as in a garden area. The trench can then be gradually filled in and covered during winter. Leaves can be placed over the trenches to add additional organic material. By spring the materials have decomposed and the area is suitable for planting.

Backyard Composting

Residents have a wide variety of options available for effective backyard composting. Home compost systems can be simple and "slow", where materials are layered in a pile or heap and turned occasionally or left to "rot". Decomposition will occur in about a year using this method. A more active home composting approach requires use of enclosed containers, attention to the proper "mix" of green and brown ingredients, and more frequent turning of materials in order to speed decomposition. Finished compost from this approach would result in around 4 – 6 months. There are a wide range of backyard composting bins suitable for home composting; bins can also be constructed using readily available materials or purchased.

Backyard Food "Digesters"

Although not technically composting, backyard "digesters" are an excellent option for home management of food scraps and vegetable grease. Digesters do not produce compost, but the systems allow these foods to decompose and generate some nutrients for the soil underneath the units. The systems produce few odors if done correctly and offer a practical deterrent against unwanted vermin. Commercial versions of home digesters, including the "Green Cone", are promoted as an option for handling virtually all types of household food organics, including meat, dairy and egg products. Do-it-yourself digesters can be easily constructed from a metal garbage can. The trick to digesters is the placement of the unit into the ground to allow for proper decomposition. Communities will gain the highest diversion benefit from promoting the use of digesters along with home composting in order to capture all household organics. Digesters are designed as an effective means of handling food wastes and pet wastes, but not yard scraps.

For more information contact Athena Lee Bradley, NERC Projects Manager.

TOXICS IN PACKAGING CLEARINGHOUSE NEWS

TPCH Elects Board Members

The Toxics in Packaging Clearinghouse (TPCH) elected the following officers to its Executive Committee for a 2-year term, beginning July 1: Ron Ohta, California, Chair; Kathleen Hennings, Iowa, Vice-Chair; and Peter Pettit, New York and David Westcott, Connecticut, Members at Large. For more information on TPCH, contact Patty Dillon, TPCH Program Manager.

STATE NEWS

VERMONT

2013 Vermont Waste Composition Study – Final Report

The Vermont Agency of Natural Resources (ANR), Waste Management and Prevention Division recently received the final report for the 2012 Vermont Waste Composition Study (WCS). This is the second time ANR has contracted to have a statewide waste sort conducted to evaluate the composition of the waste stream. The last statewide waste composition study was completed in 2001 at two locations over two seasons. With the adoption of Act 148 requiring universal recycling and mandatory organics diversion by 2020, ANR modified the study design to gather a more representative baseline of landfilled materials.

To establish a baseline picture of the composition of waste being landfilled, the 2012 study conducted sorting activities at four locations split between two seasons. The sorting locations were chosen based on their geographic region, and the availability of materials collection services offered in those regions. ANR was able to fund 100 samples sorted total (40 Residential and 60 ICI) with 55 primary sort categories. An additional 46 sub-sort categories for plastics was possible from additional funding ANR's consultant received from the Association of Post Consumer Plastic Recyclers (APR). Several sort categories selected by ANR were reflective of Act 148 bans on disposing mandatory recyclables and organic material, and an anticipated study on Vermont's Bottle Bill and single stream recycling systems.

While the differences in study design from 2001 to 2012 make it difficult to compare results, Vermont's study is able to be compared to Connecticut's and Delaware's most recent waste composition studies. Organics comprises the largest portion of the residential waste stream, while paper comprises the most for institutional/commercial/industrial (ICI). A large portion of ICI paper was comprised of cardboard and film contributed the most plastic for ICI and residential.

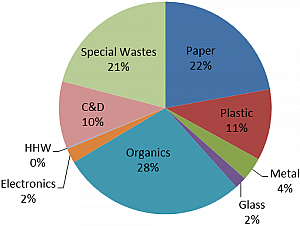

Composition of Residential MSW By Percent |

Composition of Residential MSW by Weight |

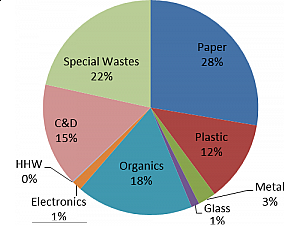

Composition of ICI MSW by Percent |

Composition of ICI MSW by Weight |

ADVISORY MEMBER NEWS

UNTHA America Offers Unique Employee Training

For many new employees, training is a matter of sitting in a classroom or spending hours on a computer, but at UNTHA shredding technology America, Inc. the emphasis is on gaining hands-on experience. Located in Hampton, NH, UNTHA America is a division of the Austrian-based UNTHA shredding technology GmbH, one of the world's leading providers of size reduction equipment for the recycling industry. Recently, UNTHA launched an exchange program between its Austrian and American headquarters, allowing new service technicians to quickly gain experience on a wide range of UNTHA shredders.

Frank Payson, who joined UNTHA America a little more than a year ago as a service technician, is already seeing the benefits of the new training program. "In the fall, our Austrian headquarters sent over an experienced service tech to work with me here in the States. Georg was here for two months and we went on the road, servicing equipment. Most of the machines we rebuilt were our popular four-shaft shredders so the training focused on those models. Georg would let me start working on the machine then jump in if I started to make a mistake or if he saw a more efficient way to do something. He did not just tell me what to do, he let me think for myself then directed me as needed. Having someone there to guide me, yet let me do the work, was the right approach. I learned a tremendous amount in a short period of time."

Earlier this spring, Payson journeyed to Austria to work in their corporate service department and gain experience on other shredder models. UNTHA produces single, two- and four-shaft shredders for a variety of industries. Currently, the four-shaft shredder is the most popular in the United States but the other models are gaining interest, and UNTHA America wants to be sure its service team is prepared.

While in Austria, Payson not only worked on servicing a wider variety of shredders, he also worked in a range of departments, including assembly, welding, painting and fabrication. "The Austrian experience was eye-opening," he says. "The service techs do everything, and the volume of work is incredible. A typical eight-man team would rebuild a couple of smaller shredders in a day. Even with larger models, the work was accomplished in record time — the service team is like a well-oiled machine. Typically, the only delay was if they had to wait on a part. UNTHA products are built to last, so sometimes we had these huge 20-year-old shredders and we had to back order parts."

Bernhard Mueggler, president and CEO of UNTHA America, explains the philosophy behind the UNTHA service model. "In Austria, service technicians are trained much differently than in the United States. In the States, technicians may specialize in just one or two areas, but in Austria, they are trained in every discipline needed to build and repair our machines. They know how to do welding, machinist work, milling and other skilled tasks. A fully trained tech such as Georg, who was with us this fall, has all the abilities needed to actually make one of our shredders from the ground up. He could run the production shop himself if need be. Having Frank get to work alongside technicians like Georg was a wonderful experience. Frank was able to gain a great deal of knowledge and bring that back to benefit our customers."

In the fall, Payson will return to Austria again to gain additional experience on some of the larger shredder models. "I am really looking forward to it," he says. "After my first trip, I came back with such an increase in confidence. I felt I truly understood these machines from the ground up. I know that my future training will only enhance what I've learned so far."

OF GENERAL INTEREST

Trainings offer Organics Best Management Practices Insights

or•gan•ics

noun

- Of, relating to, or derived from living organisms: organic matter.

- Yard and landscape trimmings — leaves, grass clippings, and tree and brush trimmings.

- Agricultural and land-clearing/forestry debris

- Manure

- Food scraps and food processing residues.

- Non-recyclable/Soiled paper — napkins, paper towels, and other paper products.2

- Items manufactured from organics — compostable bags, utensils, plates, cups and bowls made from corn and potato starch, bagasse, PLA and similar materials.

____________________________________

2 Food soiled paper usually comes from the kitchen and is not appropriate for paper recycling due to its contamination. It includes materials such as stained pizza boxes, uncoated paper cups and plates, used coffee filters, paper food cartons, napkins and paper towels. Food scraps and soiled paper together are often called "source separated organics" (SSO).

Through its "Best Management Practices for Organics and Debris Management in Rural Towns" project, NERC is working with towns and solid waste districts in Maine, New Hampshire, New York, and Vermont to develop strategies for better managing organics, from reduction to composting. The project is funded through a USDA grant.

As a part of the project, NERC is hosting organics management trainings in each participating state. These trainings serve as a gathering for decision makers, municipal officials and staff, commercial and institutional food waste generators, haulers, and others interested in advancing yard waste and food scraps reduction and composting in the Northeast. More than 170 people attended four organics management trainings offered this spring.

The "Ulster County Commercial and Institutional Food Waste Composting Summit" was held on March 21 at the New York State Department of Environmental Conservation Region 3 Headquarters in New Paltz. The workshop was very well attended with 65 participants. The event provided an overview about best management practices for managing commercial and institutional organics. Topics included: food waste composting specifics — from collection and storage to outreach and training; institutional food waste reduction and recovery; municipal composting site regulations; "meet the hauler" — food waste collection services and cost expectations; and food waste composting in action with an overview of Ulster County Resource Recovery Agency's new Organics Recovery Facility.

A "Vermont Organics Management Workshop and Roundtable" was held in April at the Vermont Technical College in Randolph, Vermont. The half-day event featured a packed agenda, including: organics best management practices — from reduction (smart landscaping, grasscycling, leaf mulching, food waste reduction) to reuse (food recovery, food to animals) and organics recycling (backyard & neighborhood composting, commercial composting); Vermont's waste composition study; composting in Vermont, including an overview of site regulations; anaerobic digestion applications for food scraps; biosolids composting in Vermont; and, food waste composting in action — featuring programs in the Central Vermont Solid Waste Management District and the Highfields Center Close The Loop Program. The event was followed by a networking lunch and Vermont Organics Partnership meeting. Thirty-five people attended the event.

The Maine Organics Management Training was held in conjunction with the annual Maine Resource Recovery Association Conference in Samoset, Maine in late April. Forty people attended the event, which qualified as a Maine Department of Environmental Protection Transfer Station Operator Training. The training featured a look at organics best management practices; a discussion of Maine regulations for yard waste and food scrap collection, storage, and processing at town transfer stations; a "how to" on conducting an organic waste assessment; residential food scrap collection options; focus on commercial food waste reduction, recovery and composting; and commercial composting in action — featuring a presentation on the Sandy River Recycling Association's compost operation in Farmington, Maine.

A "Belknap and Carroll County Organics Management Workshop and Roundtable" was held in May in Meredith, New Hampshire. The event featured an overview about best management practices for organics — yard debris, agricultural wastes, and food scraps in New Hampshire; a presentation on state composting regulations in New Hampshire; and biosolids composting in New Hampshire. The workshop was followed by a compost operation and biodiesel facility tour at Organic Matters/White Gates Farm in Tamworth. Thirty-three people attended the workshop. The workshop provided continuing education hours for New Hampshire Operator Certification.

Survey reviews of the workshops were very positive. Roundtable discussions following the trainings indicated a great deal of interest in seeing more activity on organics management, including composting of yard scraps and potentially food scraps.

NERC would like to acknowledge and appreciate its organics management project advisory members and workshop sponsors for their invaluable contribution in helping to organize the workshops:

- Ulster County Resource Recovery Agency (New York)

- New York State Department of Environmental Conservation

- Vermont Agency of Natural Resources

- Central Vermont Solid Waste Management District

- New Hampshire Department of Environmental Services

- Belknap County Conservation District (New Hampshire)

- Carroll County Conservation District (New Hampshire)

- Maine Resource Recovery Association

- Maine Department of Environmental Protection, Sustainability Unit

Two additional workshops are being planned for New York State this fall. A series of webinars will also be held. For more information contact Athena Lee Bradley, NERC Projects Manage