December 2022

New & Renewing Memberships

Renewing Sustaining Members

Renewing Supporting Members

Member Spotlight - Pratt Industries

NERC News

- NERC’s Fall Conference – Where Government & Industry Come Together

- Save the Date for NERC’s Spring Workshop

- Upcoming Webinars:

- Material Reuse Forum 2: Impact of Building Materials Reuse on Climate

- Rubber Modified Asphalt Workshop

- Strategies for Residential Food Waste Reduction & Composting

- Ground Glass Pozzolans: A More Sustainable Solution for Recycled Glass & Concrete

- Gypsum Wallboard: Problems, Recommendations, & The Current State of Recycling

- Gypsum Wallboard: Opportunities to Increase Recycling

- Steering Committee Convened for Northeast Anaerobic Digestion Project

Newly Posted

State Updates

- CONNECTICUT: Connecticut Municipalities Begin Food Scrap and Trash Co-Collection Pilot Programs

- MASSACHUSETTS: Massachusetts Department of Environmental Protection (MassDEP) Instituted New Waste Bans on November 1, 2022.

- NEW HAMPSHIRE: New Hampshire Department of Environmental Services (NHDES) publishes 2022 Solid Waste Management Plan and 2020-2021 Biennial Solid Waste Report.

Advisory Member News

- Vanguard Renewables Receives Environmental Leadership Award from Northeast Recycling Council

- APR Expands Meets Preferred Guidance Program

- AMP Robotics Raises $91 Million in Series C Financing

- AMP Robotics Develops Industry’s First AI-Powered System for Recovery of Film and Flexible Packaging

- PaintCare Year in Review: Paint Recycling Made Easy

- SalemRecycles Committee in Salem, Massachusetts held Fall Free Book Swap

- Casella Waste Systems Publishes 2022 Sustainability Report

Membership is key to Northeast Recycling Council's regional and national commitment to circularity and sustainable materials management.

Thank you to our renewing Sustaining Member, Keurig DrPepper, and our renewing Supporting Members, Mattress Recycling Coalition and Sustainable Packaging Coalition. We appreciate your commitment to Northeast Recycling Council and its mission.

For more information about NERC's Advisory Member program, please visit Nerc.org/Advisory-Members/What-Is-A-NERC-Advisory-Member and view our Advisory Membership Brochure. ADVISORY MEMBER SPOTLIGHT

Pratt Industries

New NERC Advisory Member Pratt Industries is a leader in recycling OCC. Its recycling division helps divert more than 3 million tons of materials from landfill every year. The company’s boxes and packaging supplies are manufactured from 100% recycled materials. “Pratt’s Recycling Division employs approximately 400 team members across 18 facilities who work daily to collect, sort and transport materials recovered through the recycling efforts of businesses and households.”

Founded more than 30 years ago as a family-owned business, and headquartered in the Atlanta area, Pratt Industries is now America's fifth largest corrugated packaging company. It is the world's largest, privately-held 100% recycled paper and packaging company. Last December, the company broke ground on a $500 million paper mill and box factory in Henderson, Kentucky.

NERC’s most recent Summary of Announced Increased Capacity to Use Recycled Paper report notes, “This update includes projects at 28 mills, of which 17 have been completed. The 17 completed projects include four new mills. When NERC first published this list in November 2018, it included new capacity at 17 mills, of which three projects were completed.”

Pratt’s Value Invested Program collaborates with customers to reduce operating costs; optimize productivity; and increase transportation efficiencies, all of which bring products to market more quickly. In addition to creating new products from something used, Pratt’s continued growth creates thousands of green-collar jobs across the United States.

NERC looks forward to collaborating with new Advisory Member Pratt Industries to continue to grow the company’s impressive success. The company’s involvement with NERC promises to be a mutually beneficial partnership.

NERC News

NERC’s Fall Conference – Where Government & Industry Come Together

NERC’s first in-person Conference in three years was held in Connecticut on November 3 – 4. Attendees hailed from 20 states, the District of Columbia and two Canadian Provinces. In addition to being geographically diverse, attendees were a great mix of junior and senior professionals.

The topics featured—circularity, food waste, communicating for your target audience, repurposing and reuse, recycling market development, and increasing the supply of post-consumer plastics—generated active participation by all in attendance. The mix of government and industry at the Conference also resulted in well-rounded, constructive, and in-depth discussions.

If you attended and did not fill out our brief survey yet, please consider doing so to help NERC improve future events.

If you weren’t able to attend the Conference, you can access the presentations, speaker bios, and agenda in the Conference Archives.

Conference Contact: Mary Ann Remolador

Save the Date for NERC’s Spring Workshop

Recruiting, Hiring & Retaining a Diverse Workforce

April 3 - 4, 2023

Add event to calendar

Apple Google Office 365 Outlook Outlook.com Yahoo

Check back for registration details in January at Nerc.org/Conferences-and-Workshops/Overview.

Upcoming Webinars

Material Reuse Forum 2: Impact of Building Materials Reuse on Climate

Wednesday, December 7, 2022, 11:30 am - 1:00 pm EST

Avoiding the use of new building materials is key to decreasing the built environment's impact on climate change. Come hear three speakers present studies and data about deconstruction, salvage, and reusing materials.

Presenters

- Sarah Edwards, CEO, Eunomia Research & Consulting

- Heidi Swank, Executive Director, Rethos

- Gretchen Worth, Project Director, Susan Christopherson Center for Community Planning

Sponsored by:

Rubber Modified Asphalt Workshop

Thursday, December 8, 2022, 1:00 pm - 4:00 pm EST

To register, email your contact information to: John Sheerin

Every year almost 300 million scrap tires are generated in the United States. One of the most beneficial uses involves producing Ground Tire Rubber (GTR) from scrap tires and using the GTR to create Rubber-Modified Asphalt (RMA). RMA has been used in the U.S. since the 1960s, but extensive market adoption is yet to occur, although use of rubber modified asphalt has increased approximately 50% since 2017. Depending on the application, one lane mile can use up to 2,000 scrap tires.

Join the Northeast Recycling Council, the Northeast Waste Management Officials Association and the U.S. Tire Manufacturers Association as they host a webinar to discuss performance, economic and environmental benefits of using rubber modified asphalt. This workshop will:

- Inform decision makers of the current status of this technology

- Discuss barriers to its use and the opportunities to overcome them, including lack of specifications, lack of experience in market and how state DOT’s can change regulations to allow the use of rubber modified asphalt.

Strategies for Residential Food Waste Reduction & Composting

Tuesday, December 13, 2022, 2:00 pm - 3:30 pm EST

This webinar provides an opportunity to learn about reducing food waste at home, particularly in disadvantaged communities. This is a key strategy for keeping food out of the solid waste stream. If you would like to learn more about the problems with wasting food, opportunities to reduce and divert food waste to compost, and urban community composting, join us.

Presenters

- Krishana Abrahim-Petrie, NEWMOA

- Lisa Piering, Onondaga County Resource Recovery Agency (OCRRA)

- Linda Bilsens Brolis, Institute for Local Self Reliance

- Brenda Platt, Institute for Local Self Reliance

Ground Glass Pozzolans: A More Sustainable Solution for Recycled Glass & Concrete

Wednesday, December 14, 2022, 1:30 pm - 3:00 pm EST

Using ground glass Pozzolans instead of cement in concrete is a viable and sustainable solution. If you would like to learn about this nascent industry sector that uses locally-sourced, post-consumer glass to make an environmentally preferable building material, join the webinar on Dec 14. The free webinar is co-hosted by NERC and NEWMOA. Presenters will discuss the properties, performance, applications, and environmental benefits of Pozzolans.

Presenters

- Patrick Grasso, Co-managing Partner, Urban Mining

- TJ Oneglia, Vice President of Construction Materials for O&G Industries

- Kim Bawden Program Manager at the Green Technology Accelerator Center (GTAC) and Senior Staff Engineer at the NYS Pollution Prevention Institute at RIT

Gypsum Wallboard: Problems, Recommendations, & The Current State of Recycling (Webinar 1 of 2)

Monday, January 9, 2023, 1:00 pm - 3:00 pm EST

Gypsum Wallboard: Opportunities to Increase Recycling (Webinar 2 of 2)

Tuesday, January 24, 2023, 1:30 pm - 3:00 pm EST

Steering Committee Convened for Northeast Anaerobic Digestion Project

The Northeast Waste Management Officials’ Association (NEWMOA), the Northeast Recycling Council (NERC), Clean & Healthy New York, and the Connecticut Coalition for Economic and Environmental Justice are partnering on a two-year anaerobic digestion (AD) project— Developing Solutions to Regulatory Challenges and Engaging Community Support to Expand Diversion of Food Waste to Anaerobic Digestion in the Northeast. The US EPA-funded project will develop solutions to regulatory and other barriers to AD while incorporating principles of Environmental Justice (EJ) and community engagement. Supporting engagement of EJ communities with local AD facilities that are planned or already exist is also part of the project.

NEWMOA and NERC and our partners, Clean + Healthy and the Connecticut Coalition for Economic and Environmental Justice, are very excited to be working with such a distinguished and knowledgeable group of stakeholders on this anaerobic digestion project. The involvement of so many key people will help ensure the success of this effort. We greatly appreciate EPA’s support for this innovative initiative, said Terri Goldberg, Executive Director of NEWMOA.

A Steering Committee has been convened to lend their expertise and guidance about the project content and deliverables, review the publications to be developed, and promote the training webinars. Members include:

- Nora Goldstein, BioCycle

- Coryanne Mansell, Center for EcoTechnology

- Joanne Shafer, Centre County Recycling & Refuse Authority

- Bobbi Wilding, Clean+Healthy (formerly Clean and Healthy New York)

- Jed Thorp, Clean Water Action Rhode Island

- Sharon Lewis, Connecticut Coalition for Economic and Environmental Justice

- Suzanne Hunt, Generate Capital

- Amelia Rose, Groundwork Rhode Island

- Randy Hartmann, Keep America Beautiful

- John Fischer, Massachusetts Department of Environmental Protection

- Jennifer McDonnell, New York City Department of Sanitation

- Melissa Hall, New York State Pollution Prevention Institute

- Mary Ann Remolador, NERC

- Krishana Abrahim-Petrie, NEWMOA

- Terri Goldberg, NEWMOA

- Jennifer Griffith, NEWMOA

- Matthew Karmel, Esq., Offit Kurman P.A.

- Debra Darby, Tetra Tech

- Christine Beling, US EPA, Region 1

- Rachel Chaput, US EPA, Region 2

- Stephanie Lansing, University of Maryland

- Billy Connelly, Vanguard Renewables

- Anne Bjur, Vermont Agency of Natural Resources

- Josh Kelly, Vermont Agency of Natural Resources

Any questions can be directed to Mary Ann Remoladar, Assistant Director, Northeast Recycling Council at maryann@nerc.org.

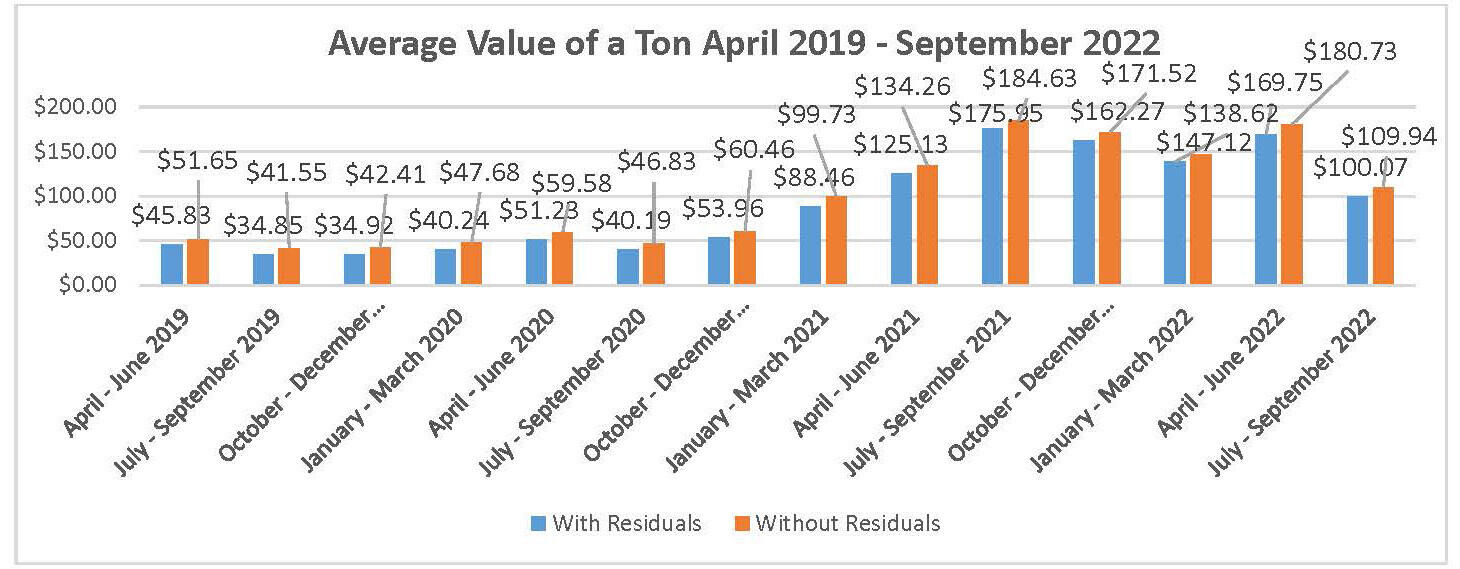

NEWLY POSTEDSharp Downward Trend in Material Values for Quarter Ending September 30

The NERC quarterly MRF Values Survey for the period July – September 2022, showed a sharp downward trend in values. This is the 14th in NERC’s series of quarterly reports on the market value of commodities from MRFs in the Northeast. This report includes information from eight states: Delaware, Maine, Maryland, Massachusetts, New Jersey, New York, Pennsylvania, and Virginia.

These survey results reflect the differing laws and collection options in the participating states. Four of the states have beverage container deposit laws. As a result, fewer glass bottles, PET bottles and aluminum cans are processed in MRFs in those states. Those MRFs are also likely to have less revenue from those recyclables. In addition, the report reflects a mix of single stream, dual stream and source separation to collect recyclables with single stream being the most common approach. The type of collection used will have an impact on MRF design and operation. Thus, the data from this report reflects the unique blend of facilities and statewide laws in the reporting states.

Current report: NERC Northeast Recycling Market Report November 2022

State News

CONNECTICUT

Connecticut Municipalities Begin Food Scrap and Trash Co-Collection Pilot Programs

This month, the City of West Haven and the City of Middletown launched curbside food scrap and unit-based pricing for trash co-collection pilot programs. Using special green bags for food scraps and orange bags for trash,16,000 households in West Haven and 2,800 households in Middletown are separating the two material streams which will be co-collected at the curb. The materials for both communities are transported by municipal fleet and delivered to a CT DEEP permitted facility in Wallingford, CT for sorting - the green food scrap bags are sent to Quantum Biopower and the orange trash bags are sent to an in-state waste-to-energy facility.

The programs are funded by CT DEEP’s Sustainable Materials Management (SMM) Grant program. Nearly $5 million in SMM grants were awarded to programs that support the development of food scrap collection and unit-based pricing pilot programs, the type of waste diversion efforts recommended by the Connecticut Coalition for Sustainable Materials Management (CCSMM), a coalition of over 100 municipalities across the state working on ways to reduce waste and increase reuse and recycling.

Fifteen municipalities were approved to receive grants and launch a variety of transfer station and curbside food scrap and unit-based pricing pilots: Ansonia, Bethany, Deep River, Guilford, Madison, Meriden, Middletown, Newtown, Seymour, Stonington, Rocky Hill, West Hartford, West Haven, Woodbridge, and Woodbury. Three regional groups have been approved to receive grants to support the municipal SMM pilots: South Central Regional Council of Governments (SCRCOG), Naugatuck Valley Council of Governments (NVCOG) and Housatonic Resources Regional Authority (HRRA).

Many of the SMM grant applicants modeled their pilots off a successful pilot program the City of Meriden launched earlier this year with DEEP SMART grant program funding. The Meriden pilot was a 4-month, 1,000-household test to prove the feasibility of co-collection of food and household waste and the ease-of use for residents; the pilot diverted over 13 tons of food scraps from the waste stream. The Meriden project received broad interest from residents, including those not part of the pilot.

Connecticut relies heavily on aging disposal infrastructure through which the majority of solid waste is incinerated to generate energy. The pilot programs are designed to reduce the amount of trash in these communities and reduce reliance on this infrastructure or out of-state-landfills. With the July 2022 closure of the Hartford Resource Recovery Facility owned by the Materials Innovation and Recycling Authority (MIRA), up to 30% of the state’s solid waste will now be shipped to out-of-state landfills. The pilot projects will help meet Connecticut’s goals to reduce waste and increase reuse, recycling and composting, while also creating stable, predictable, environmentally sound and self-sufficient waste disposal options.

For more information about the pilot programs, please contact Jennifer Weymouth at CT DEEP.

MASSACHUSETTS

MassDEP New Waste Bans

MassDEP instituted new regulations on November 1, 2022 that ban the disposal of mattresses and textiles in the trash, as well as decrease the threshold of food waste from businesses and institutions to one ton or more per week to a half-ton per week.

MassDEP first established a ban on disposal of food waste from businesses and institutions disposing of one ton or more per week in 2014, which increased food waste diversion from 100,000 tons per year to more than 300,000 tons per year, while also creating hundreds of new jobs and increasing the gross state product by $77 million. An estimated 4,000 businesses will be subject to the new threshold. MassDEP has supported the food waste ban by providing grants to businesses establishing or expanding capacity to manage food waste, including anaerobic digestion and composting operations.

Textiles represent another important opportunity for Massachusetts to reduce the waste stream and capture valuable resources. Each year, the Commonwealth throws out more than 200,000 tons of textiles in the trash. This includes old clothing, as well as towels, linens, bags, belts, and shoes. Fortunately, Massachusetts has an extensive collection infrastructure of both non-profit and for-profit textile recovery organizations that can find a new use for these materials, either through selling or donating for reuse, or recycling into products such as carpet padding, insulation, or wiping rags.

Mattresses are a difficult material to manage at solid waste facilities and take up a large amount of space in landfills. More than 75 precent of mattresses components can be separated and recycled, including metal, wood, fabric, and padding. Massachusetts generates approximately 600,000 unwanted mattresses per year, about 200,000 of them from residents, with the rest coming from businesses and institutions. MassDEP has provided grants to help establish mattress recycling programs in 137 municipalities.

Johnny's Luncheonette Case Study - The iconic Newton diner and 2022 MassRecycle award winner, has exemplary recycling and food waste diversion programs. The diner partners with local environmental groups such as Green Newton on a variety of sustainability initiatives, and shares information on their food scraps composting program with customers through interactive signage. Collecting both pre- and post-consumer food waste, Johnny’s Luncheonette diverts 600-700 pounds of organics per week for composting with Black Earth Compost.

Structure Tone Case Study - Structure Tone, a commercial construction manager applied best practices for on-site source separation of construction and demolition materials during an office space renovation project in Cambridge. Keys to success included careful planning, thorough staff training, creative on-site material collection strategies, and close coordination with their recycling hauler. This project resulted in the collection of 6.78 tons of source separated material for recycling.

NEW HAMPSHIRE

2022 New Hampshire Solid Waste Management Plan is Now Available

Concord, NH – The New Hampshire Department of Environmental Services (NHDES) is pleased to announce the publication of the 2022 New Hampshire Solid Waste Management Plan ![]() , which is now available on NHDES’ website. Prepared pursuant to RSA 149-M:29, I, the Solid Waste Management Plan is a ten-year, high-level plan outlining goals, strategies and actions to improve solid waste management in New Hampshire.

, which is now available on NHDES’ website. Prepared pursuant to RSA 149-M:29, I, the Solid Waste Management Plan is a ten-year, high-level plan outlining goals, strategies and actions to improve solid waste management in New Hampshire.

How we manage solid waste affects every citizen and visitor to our state and is a topic of keen interest. During the public comment period for this plan, NHDES received input from 74 individuals and organizations. The Plan incorporates suggestions received through these public comments and from the New Hampshire Solid Waste Working Group.

In a cover letter issued with the Plan, NHDES Commissioner Robert Scott said, “The level of attention and concern demonstrated through these comments bodes well for New Hampshire’s success in achieving the plan’s goals, because success will depend upon active participation from everyone.”

NHDES is excited to work with such engaged stakeholders, and to begin implementing the strategies and actions that the plan sets forth, to build a better, more sustainable solid waste management system for New Hampshire.

Additionally, NHDES published its Biennial Solid Waste Report for 2020-2021.

Advisory Member News

Vanguard Renewables Receives Environmental Leadership Award from Northeast Recycling Council

Vanguard Renewables was awarded the 2022 Northeast Recycling Council (NERC) Environmental Sustainability Leadership Award at NERC’s Fall Conference recently held in Connecticut.

“Vanguard Renewables is changing the way that the country views food waste,” stated Neil H. Smith, Chief Executive Officer, Vanguard Renewables. “We are honored that NERC has recognized our company for the vital role we are playing to help divert inedible food and beverage waste from landfills and incinerators and recycling that into something powerful for our planet – renewable natural gas.” Read the full press release here.

APR Expands Meets Preferred Guidance Program

The Association of Plastic Recyclers (APR) has announced a new packaging component to be included in the Meets Preferred Guidance (MPG) Program which recognizes materials, packaging components, and complete packages composed of PET, HDPE, PP, and PE film that are considered Preferred according to the APR Design® Guide for Plastics Recyclability. Near Infrared (NIR) sortable dark color concentrates are now eligible for the program.

“Dark colored plastics have historically been landfilled because the concentrates used to make the color absorb light in the NIR spectrum which the optical sorters need to identify and sort the package,” stated Curt Cozart, APR COO. “NIR sortable dark color concentrates allow these packages to be recovered because they don’t absorb this light. This is extremely impactful in a time where the industry needs more supply.”

The program also now includes a more streamlined online submission process designed to clarify submission requirements, facilitate the transmittal of data, and provide better tracking. This updated submission process allows the next candidates to be rolled out more quickly. Upcoming candidate products include:

- Film Labels Fixed to a PET Container with an Adhesive

- Film Labels and Direct Print Labels that do not employ an Adhesive

- Hot Caustic Resistant and Washable Inks for Labels for PET Packaging

- Closures affixed to PET Packages

- Closures affixed to HDPE Packages

- PET Base Resin

- HDPE Base resin

Visit the APR website for more information about the Meets Preferred Guidance Program, as well as other APR Recognition Programs.

“Advancements in robotics and automation are accelerating the transformation of traditional infrastructure, and AMP is seeking to reshape the waste and recycling industries," said Michael DeLucia, sector lead for Climate Investing, Wellington Management. "By bringing digital intelligence to the recycling industry, AMP can sort waste streams and extract additional value beyond what is otherwise possible.”

AMP will use the latest funding to scale its business operations while continuing its international expansion. Demand for robotics to retrofit existing recycling infrastructure continues to thrive; among historic demand for recycled commodities of all types, the industry needs capacity to meet the 2025 goals of consumer packaged goods companies that have committed to the use of post-consumer recycled (PCR) content. The company’s core technology business has grown accordingly; the new capital will enhance manufacturing capacity to support a fleet of approximately 275 robots around the world and further AMP’s ongoing development of AI-enabled automation applications for recycling, like AMP Vortex™, the company’s latest innovation for recovery of film and flexible packaging. AMP also has three production facilities in the Denver, Atlanta, and Cleveland metropolitan areas; the funding will help drive further growth of the company’s secondary sortation business in the United States. Read the full press release here.

A mere 1 percent of U.S. households have curbside access for recycling film and flexible packaging today, estimates The Recycling Partnership. Yet film and flexibles comprise the fast-growing and second-largest valued packaging segment, behind only corrugated containers and ahead of bottles and other rigid plastic packaging. Close to 95 pounds of these materials, including grocery and storage bags, pouches, and wrappers, are found in the average U.S. home each year.

The recycling industry lacks infrastructure for the identification and separation of film and flexible packaging, and these materials jam MRF equipment not designed to handle it. Even 2 to 3 percent film in overall MRF streams can be unmanageable to remove manually, often damaging equipment, necessitating downtime, and hindering recovery of recyclables. Film and flexible packaging find their way into every line in a MRF, resulting in high levels of contamination. But most of these materials, given their light weights, make their way onto fiber lines. Film contamination degrades fiber bale purity, leading to revenue loss or the need for additional post-processing downstream.

AMP’s solution, AMP Vortex™, is the industry’s first AI-powered automation system for film removal and recovery in MRF environments. AMP’s system targets film contamination and is initially optimized for quality control on fiber lines. Vortex provides the industry with the most flexible and adaptable solution targeting film; it can be deployed as a retrofit solution in various configurations to accommodate different belt sizes and inclines. Read the full press release here.

PaintCare Year in Review: Paint Recycling Made Easy

For over a decade, PaintCare has been operating manufacturer-led paint stewardship programs in states across the country that make paint recycling more convenient. PaintCare is the nonprofit organization created by the paint industry through the American Coatings Association to manage the end of life of paint products in states that pass paint stewardship laws. The organization currently operates programs in California, Colorado, Connecticut, District of Columbia, Maine, Minnesota, New York, Oregon, Rhode Island, Vermont, and Washington.

As a proud advisory member of NERC, PaintCare continues to work diligently to ensure that households and businesses have convenient, year-round access to drop-off sites where paint products like paint, stain, and varnish are collected for recycling. To date, PaintCare has collected more than 60 million gallons of paint, 71% of which has been recycled back into paint.

These drop-off sites serve a community need for easier recycling opportunities and keep paint out of the waste stream. PaintCare currently provides a network of 2,380 drop-off sites in its program states, which are easily found using the PaintCare drop-off site locator.

The New York PaintCare program launched on May 1, 2022, and since then PaintCare has set up 260 drop-off site locations where residents may take their leftover paint for recycling. PaintCare is glad to have New York join the program and make paint recycling more widely available to residents in the state.

In addition to providing convenient paint recycling at drop-off sites, PaintCare offers services to alleviate the burden of recycling larger quantities of paint. PaintCare has provided over 7,000 free large volume pickups for customers with 100 gallons of paint or more to date. These large volume pickups are a helpful way to relieve your basement or garage of stored paint. Learn more about how to schedule a pickup.

PaintCare continues to build upon their success by partnering with industry organizations such as NERC. For more information about paint recycling, requesting a large volume pickup, or other questions, please visit PaintCare at www.paintcare.org or call us at (855) PAINT-09.

SalemRecycles Committee in Salem, Massachusetts held Fall Free Book Swap

The SalemRecycles Committee in Salem, Massachusetts held their Fall Free Book Swap on Saturday November 12th. This event provides the opportunity for Salem residents to donate books they’ve accumulated and/or join the event and take home as many books as their hearts desire! Other items accepted at the event include reusable bags, DVD’s, Records, CD’s, puzzles, and greeting cards.

In order to successfully run this event, there were 50 volunteers who spent their time unloading donations and sorting the items into categories. This event also welcomed nearly 550 attendees on Saturday! At the end of the event, all leftover materials were taken by Discover Books to be reused or recycled.

If you have any questions regarding this event, please contact Janelle Rolke at jrolke@salem.com or visit www.greensalem.com to view other upcoming SalemRecycles events in Salem, MA.

Casella Waste Systems Publishes 2022 Sustainability Report

Casella Waste Systems, Inc. (Nasdaq: CWST) recently published its 2022 Sustainability Report today, outlining the company’s progress toward its sustainability vision, while elevating five key sustainability metrics to the forefront of its strategic goals.

Casella Waste Systems, Inc. (Nasdaq: CWST) recently published its 2022 Sustainability Report today, outlining the company’s progress toward its sustainability vision, while elevating five key sustainability metrics to the forefront of its strategic goals.

“With this year’s report, we introduce a distilled focus on five primary goals,” said Casella Chairman and Chief Executive Officer, John W. Casella. “While we intend to continue internally measuring our performance against many key sustainability indicators, we believe that elevating our five primary metrics will allow us to maintain a high level of focus around our most important and impactful 2030 goals.”

Casella’s five key elements to its sustainability strategy include metrics focused on the people who work for the company, the materials the company manages, the operations that manage those materials, the emissions those operations produce, and the communities in which the company operates. For each element, Casella has established a primary metric and a 2030 goal as well as additional factors that will help the company advance its sustainability vision.

“This Report showcases the progress we have made since we introduced our Sustainability Goals in 2020, while also recognizing the changing environment in which we operate,” Casella said. “It is increasingly important to all our key stakeholders that we remain both economically and environmentally sustainable. Our industry is evolving, and our company is proud to be one of the leaders of this evolution.”

Casella’s history as a leader in sustainability is marked by several milestones in materials management featured in the report, and its focus on climate leadership has been present for nearly two decades.

As the only waste and recycling company among the founding members of the EPA Climate Leaders program, Casella reduced its carbon footprint by 45% from 2005 to 2010. The company’s climate achievements were recognized in 2012 by the EPA, the Association of Climate Change Officers, the Center for Climate and Energy Solutions, and the Climate Registry with a Climate Leadership Award for Excellence in GHG management. Casella’s first sustainability report was issued in 2009. A pioneer in sustainable waste and recycling innovation, Casella established the first recycling facility in Vermont in 1977 and, was a charter member of the EPA Climate Leaders program, and the 2022 Sustainability Report is the company’s sixth biennial report on its sustainability activities. Download Casella's 2022 Sustainability Report.